WIENANDT Performance Technology Dynamometer Test Lab capabilities

$45+ years of engine development experience

4 dynos currently operational, Complete Data Acquisition

$45+ years of engine development experience

4 dynos currently operational, Complete Data Acquisition

Dyno #1 Stuska Water Brake, 180 hp capacity 12000 rpm

Vertical Application for outboard, using a dedicated driveshaft housing for correct exhaust tuning.

Drive shaft connects directly to the crank shaft

This machine will run from 10 to 180 hp with a 10,000 rpm limit. We have dedicated exhaust housings for A OMC, 15 Mercs, Hot Rods, 25 and 44 Mercs, Sport C Tohatsu, 50 D Tohatsu, SST 45, and SST 60 engines.

Drive shaft connects directly to the crank shaft

This machine will run from 10 to 180 hp with a 10,000 rpm limit. We have dedicated exhaust housings for A OMC, 15 Mercs, Hot Rods, 25 and 44 Mercs, Sport C Tohatsu, 50 D Tohatsu, SST 45, and SST 60 engines.

Dyno #9 Froude Eddy Current dyno mounted vertical for high RPM applications

2:1 ration reduction for high rpm engines up to 18,000 rpm

Custom built stand can run direct drive to 9,000 rpms or with 2:1 belt reduction to 18,000 rpms

Two fuel flow monitors for two carbs or EFI system. Total variable water control cooling engine.

Complete data collection system.

Com

Custom built stand can run direct drive to 9,000 rpms or with 2:1 belt reduction to 18,000 rpms

Two fuel flow monitors for two carbs or EFI system. Total variable water control cooling engine.

Complete data collection system.

Com

Dyno # 6 Froude Eddy Current 90 hp at 9000 rpm

Horizontal set up

Direct drive to crank via coupler

Incredible engine control and repeatability.

Direct drive to crank via coupler

Incredible engine control and repeatability.

Dyno #10 Taylor DE150 Eddy Current 2000 hp, 12000 rpms

Our newest addition to the lab. Horizontal application. Very versatile mounting for many applications.

All of our dynos are purchased dyno brakes mounted on custom made frames for our applications. Two Vertical and two Horizontal Dynos connected directly to the crankshaft. Frames can be custom built for your needs.

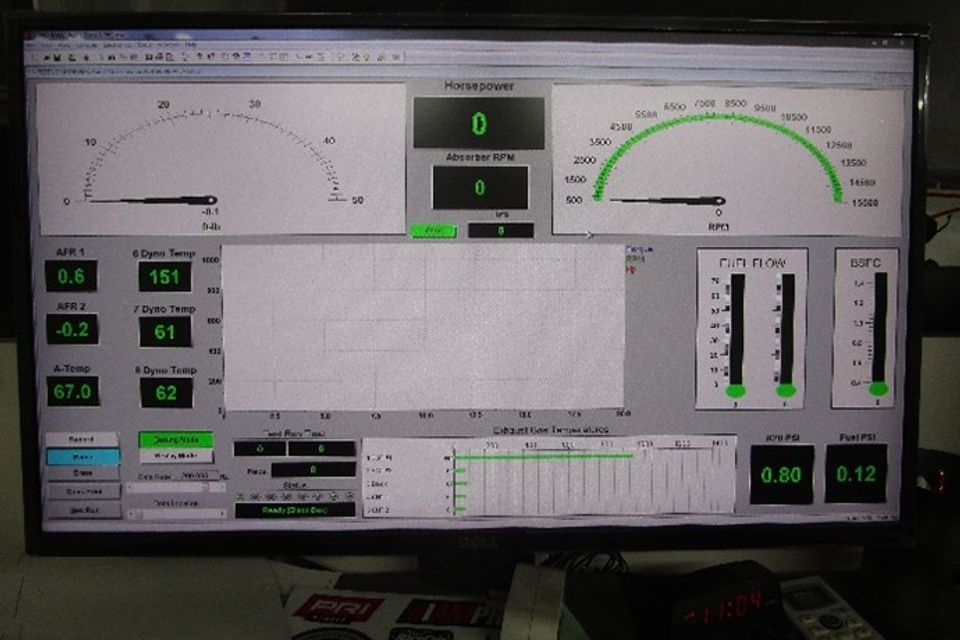

Dyno Data Acquisition Systems are Power Test-DynoMite Pro data systems. And Aim Data collection. Total automated collection system. Rpm, Torque, Fuel Flow, BSFC, Many Temps and Pressures. Two Channel Lambda if requested. Kistler in cylinder pressures available. Outputs Notes, Charts and Graphs.

You get complete data and summary reports.

Mike bought his first new Dyno in 1978 from Harv Stuska. Since them owned many. Also was Dyno operator at Wienandt Machine, FAST Inc, Aarrow Performance, Mercury Performance Craft, Mercury Racing, XRDI and now Wienandt Performance. Very few have a better understanding of Dynamometers and how to achieves the end goals.

Why use a Dynamometer? Many reasons depending on your application.

Outboard racers: The dyno is a tool that we use to break-in new engines. By controlling the Load vs RPM and cooling. Think of the time you won’t have to waste just riding around. We can seat pistons and rings better than is possible in the field with controlled loads. We have a preprogramed layout for wearing the engine in, not out. We can control the cooling and monitor all temps and pressures. Following the break-in process we then do final race tuning to get the most out of the engine. We provide Power Curves and Torques curves so you can tune your boat and propellers for a winning setup. We can provide a drop on powerhead all tuned and ready.

Snowmobile racers: Have somewhat different challenges. Again, we can break-in an engine better by completely controlling the load at every RPM and being able to control all aspects. Once completing the break-in, performance tuning begins. Different Spark advances are tried, balancing with jetting changes. Identifying the Torque curve is absolutely critical for knowing how to prepare the clutch. Fuel testing, spark plug testing, even so fine as to change the spark plug gap we can measure and record the differences. You get all paperwork and a summary sheet on all test. Many race shops don’t let those records out. This is your engine and you are paying for the testing, we do everything possible to teach you what you need to know to make it a success for you.

OEM new engine development: From commercial engines to military specific fuel engines testing for performance targets are a small thing compared to the design durability targets. Powerband development for application with temperature controls along with fuel efficiency development and designing parts to carry the loads this tool is a must.

This is not only a time saver for you but a performance advantage. Without data, you just another person with an opinion. When you win, we win.

Dyno Data Acquisition Systems are Power Test-DynoMite Pro data systems. And Aim Data collection. Total automated collection system. Rpm, Torque, Fuel Flow, BSFC, Many Temps and Pressures. Two Channel Lambda if requested. Kistler in cylinder pressures available. Outputs Notes, Charts and Graphs.

You get complete data and summary reports.

Mike bought his first new Dyno in 1978 from Harv Stuska. Since them owned many. Also was Dyno operator at Wienandt Machine, FAST Inc, Aarrow Performance, Mercury Performance Craft, Mercury Racing, XRDI and now Wienandt Performance. Very few have a better understanding of Dynamometers and how to achieves the end goals.

Why use a Dynamometer? Many reasons depending on your application.

Outboard racers: The dyno is a tool that we use to break-in new engines. By controlling the Load vs RPM and cooling. Think of the time you won’t have to waste just riding around. We can seat pistons and rings better than is possible in the field with controlled loads. We have a preprogramed layout for wearing the engine in, not out. We can control the cooling and monitor all temps and pressures. Following the break-in process we then do final race tuning to get the most out of the engine. We provide Power Curves and Torques curves so you can tune your boat and propellers for a winning setup. We can provide a drop on powerhead all tuned and ready.

Snowmobile racers: Have somewhat different challenges. Again, we can break-in an engine better by completely controlling the load at every RPM and being able to control all aspects. Once completing the break-in, performance tuning begins. Different Spark advances are tried, balancing with jetting changes. Identifying the Torque curve is absolutely critical for knowing how to prepare the clutch. Fuel testing, spark plug testing, even so fine as to change the spark plug gap we can measure and record the differences. You get all paperwork and a summary sheet on all test. Many race shops don’t let those records out. This is your engine and you are paying for the testing, we do everything possible to teach you what you need to know to make it a success for you.

OEM new engine development: From commercial engines to military specific fuel engines testing for performance targets are a small thing compared to the design durability targets. Powerband development for application with temperature controls along with fuel efficiency development and designing parts to carry the loads this tool is a must.

This is not only a time saver for you but a performance advantage. Without data, you just another person with an opinion. When you win, we win.